| Eastern Motorcycle

Parts number |

Replaces OEM |

Description |

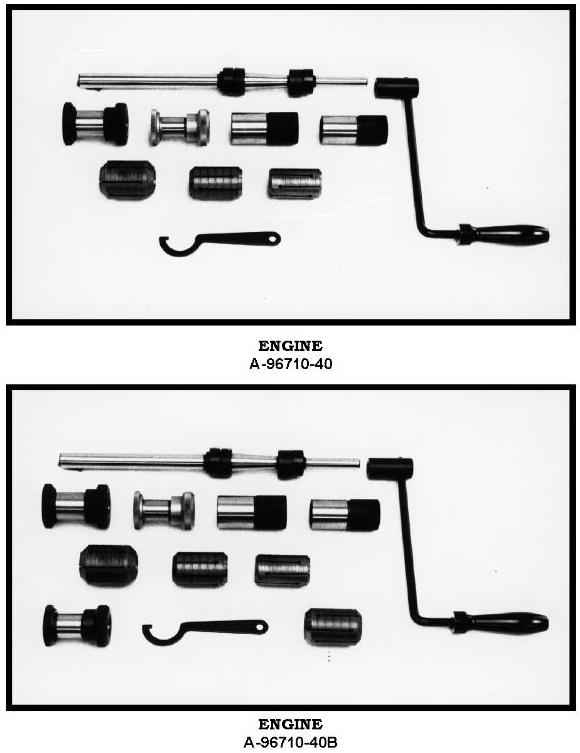

| A-96710-40 |

96710-40 |

Crankcase lapping tool, engine, Big Twin

1929-present, Sportster 1952-1976. |

| A-96710-40B |

|

Crankcase lapping tool, engine, Big Twin 1929-present, Sportster

1952-.

Includes extra lap head and pilot: 96718-88 (1.562) for Sportster 1987-present. |

| A-96710-77 |

|

Transmission lapping tool, Big Twin 1936-1976, Sportster

1952-1983. |

| A-96710-78 |

|

Lap head, transmission, 1.300" cast iron, Sportster 1952-1984. |

| A-96710-79 |

|

Lap head, transmission, 1.870" cast iron, Big Twin 1936-1977. |

| A-96710-80 |

|

Engine and transmission lapping tool, Big Twin 1930-present,

Sportster 1954-1977. |

| A-96710-85 |

|

Lap head and pilot, transmission, 1.870" cast iron, Big Twin

1937-1977. |

| A-96710-87 |

|

Lap head and pilot, transmission, 1.300" cast iron, Sportster

1952-1984. |

| A-96710-89 |

|

Lap head and pilot, engine, 1.562" cast iron, Sportster

1987-present. |

| A-96711-81 |

|

Spanner wrench for lapping tools, Big Twin 1930-present, Sportster

1952-1977. |

| A-96712-40 |

96712-40 |

Lapping shaft only, engine (with nuts and spacers), Big Twin

1930-present, Sportster 1952-1977. |

| A-96712-40A |

|

Lapping shaft only, transmission (with nuts and spacers), Big Twin

1930-present, Sportster 1952-1977. |

| A-96714-40 |

96713-40 96714-40 |

Drive handle and arbor, engine and transmission, Big Twin

1930-present, Sportster 1952-1976. |

| A-96715-40 |

96715-40 |

Guide sleeve, engine lapping tool, 1-1/2", Big Twin 1930-1954. |

| A-96716-40 |

96716-40 |

Guide sleeve, engine lapping tool, 1-3/8", Big Twin 1955-1957,

forty-five 1929-1973. |

| A-96717-40 |

96717-40 |

Lap head, engine, 1.500" cast iron, Big Twin 1930-1954. |

| A-96718-40 |

96718-40 |

Lap head, engine, 1.375" cast iron, Big Twin 1955-1957, Sportster

1954-1976. |

| A-96718-58 |

96718-58 |

Lap head, engine, 1.750" cast iron, Big Twin 1958-present. |

| A-96718-88 |

|

Lap head, pinion shaft, 1.562" cast iron, Sportster 1987-present. |

| A-96727-56 |

96727-56A |

Guide sleeve, engine lapping tools, Timken bearings, Big Twin

1955-present. |

| A-96728-56 |

96728-56A |

Guide sleeve, engine lapping tools, Timken bearings, Sportster

1954-1976. |

| A-96728-77 |

96728-77 |

Guide sleeve, engine lapping tools, Timken bearings, Sportster

1977-present. |

|

|